Since the launch of the REV Gen 4 platform, BRP has been using a Patent Pending technology on the pDrive clutch to minimize engine vibration. This unique new solution adds no weight but solves the vibration issue many large displacement two-cylinder snowmobile engines experience. To minimize vibration from the extra 50cc’s, extra 10 horsepower and 30% faster response of the Rotax 850 E-TEC, Ski-Doo engineers designed an industry first, counterbalancing pDrive fixed clutch sheave.

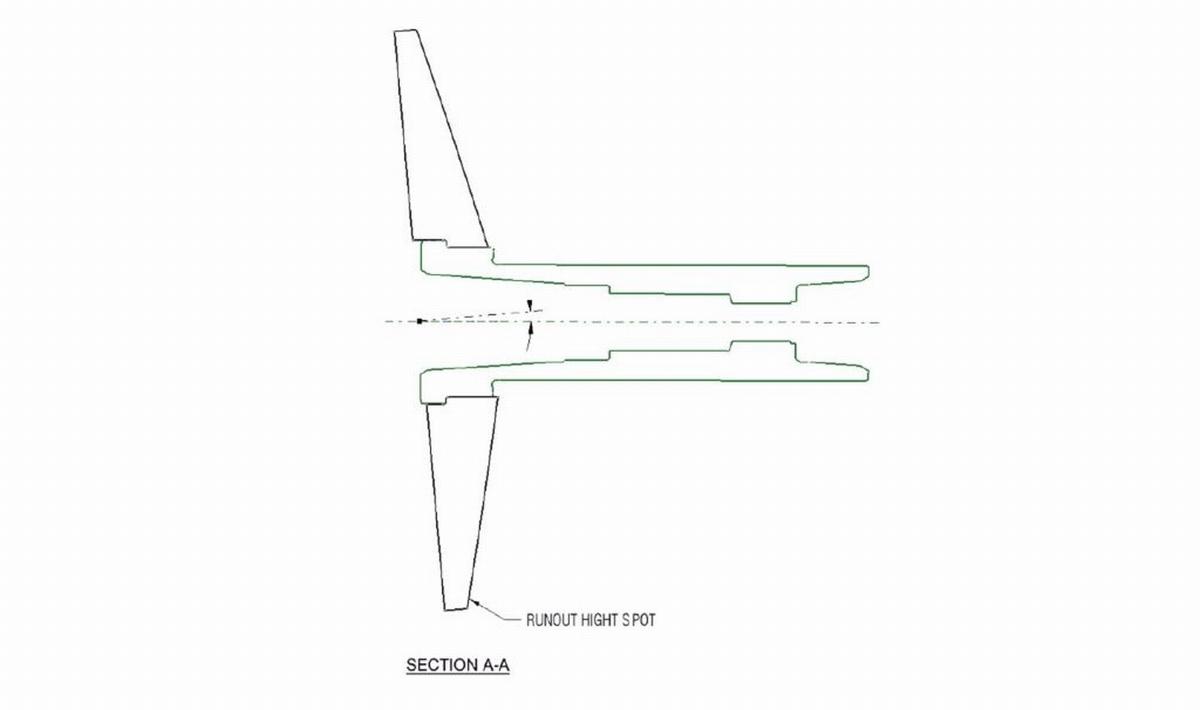

Those with a keen technical eye will notice the D-Shaped crankshaft alignment and the twenty four thousandths (.024) of an inch (.6mm) precise offset or runout built into the clutch sheave. This runout keeps the belt more perfectly tensioned within the primary and secondary clutches to reduce vibrations sent into the chassis through the secondary clutch.

The timing of the runout’s high spot meeting the belt is synchronized with the engine’s firing to offer a counterbalancing effect without added weight or complexity. The net result is less vibration transferred into the chassis and the rider.

Because of reduced vibration transferred to the belt, the belt temperature remains stable or even cooler, compared to not having this runout.